Unleashing Power and Efficiency with Kohler Diesel Engines in Modern Machinery

In the rapidly evolving landscape of modern machinery, the demand for reliable and efficient power sources is greater than ever. According to industry reports, the global diesel engine market is projected to reach over $180 billion by 2025, with a significant portion attributed to advancements in technology and sustainability.

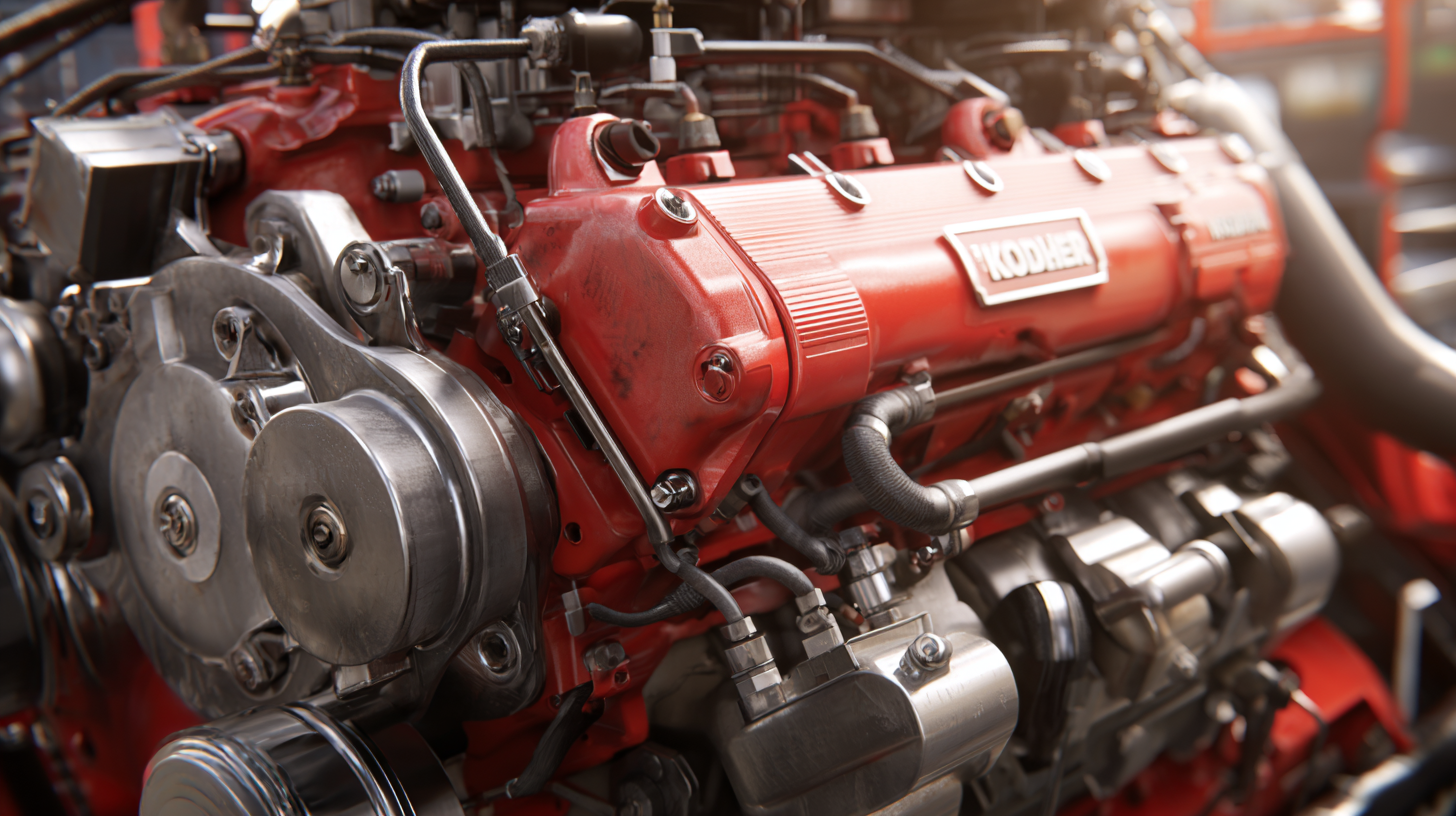

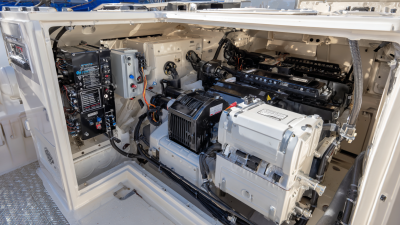

Kohler diesel engines stand out as a leading choice, integrating innovative design with exceptional performance to meet the needs of various applications, from construction to agriculture. Renowned for their durability and fuel efficiency, Kohler diesel engines not only enhance operational productivity but also contribute to reducing overall emissions, aligning with the industry's shift towards greener solutions.

This guide will explore how to maximize the potential of Kohler diesel engines in modern machinery, harnessing their power while maintaining efficiency and sustainability in equipment design and usage.

Understanding the Role of Kohler Diesel Engines in Today's Machinery

Kohler diesel engines play a crucial role in powering modern machinery across various industries. Renowned for their reliability and robustness, these engines are designed to deliver high performance while ensuring fuel efficiency. This is particularly important in sectors such as agriculture, construction, and transportation, where machinery operates under demanding conditions for extended periods. Kohler has successfully integrated advanced engineering technologies into their diesel engines, optimizing them for both power and durability, which in turn minimizes downtime and maintenance costs.

Kohler diesel engines play a crucial role in powering modern machinery across various industries. Renowned for their reliability and robustness, these engines are designed to deliver high performance while ensuring fuel efficiency. This is particularly important in sectors such as agriculture, construction, and transportation, where machinery operates under demanding conditions for extended periods. Kohler has successfully integrated advanced engineering technologies into their diesel engines, optimizing them for both power and durability, which in turn minimizes downtime and maintenance costs.

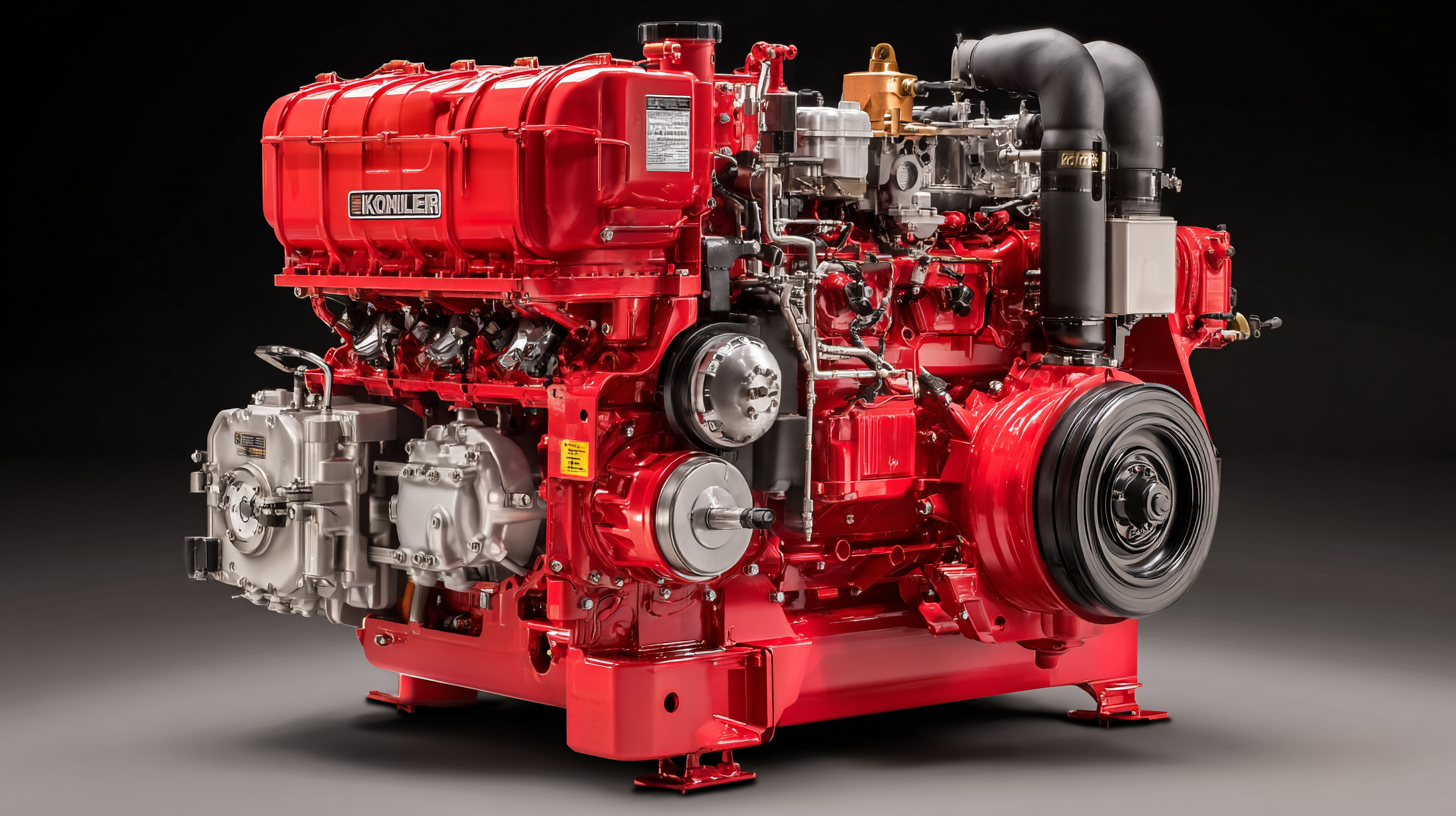

Moreover, the adaptability of Kohler diesel engines makes them suitable for a wide range of applications, from compact construction equipment to large agricultural machines. Their ability to produce consistent torque and horsepower at various RPMs enhances the functionality of modern machinery, allowing operators to achieve higher productivity levels. Furthermore, with ongoing innovations focused on reducing emissions, Kohler diesel engines also meet the stringent environmental regulations that are increasingly pivotal in today’s industrial landscape, demonstrating that efficiency and sustainability can go hand in hand.

Key Features of Kohler Diesel Engines for Enhanced Performance

Kohler diesel engines are designed with an array of key features that significantly enhance performance in modern machinery. One of the most notable aspects is their advanced fuel efficiency. Equipped with cutting-edge injection systems, these engines optimize fuel consumption while delivering robust power, making them ideal for heavy-duty applications. This efficiency not only reduces operational costs but also minimizes the environmental impact, aligning with the growing demand for sustainable machinery solutions.

Another essential feature is their exceptional durability. Kohler diesel engines are built using high-quality materials and innovative engineering techniques, ensuring reliability even under the most challenging conditions. Their rugged construction allows for prolonged service intervals and reduced maintenance needs, which is a critical advantage for operators seeking to maximize uptime. Additionally, these engines often come with advanced cooling systems and noise-reduction technologies, enhancing their adaptability across various industrial and commercial applications.

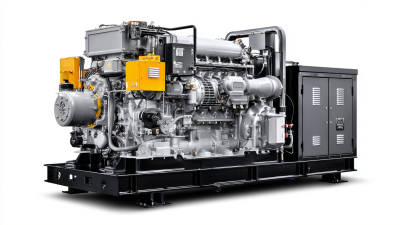

Performance Comparison of Diesel Engines in Modern Machinery

Maximizing Fuel Efficiency with Kohler Diesel Technology

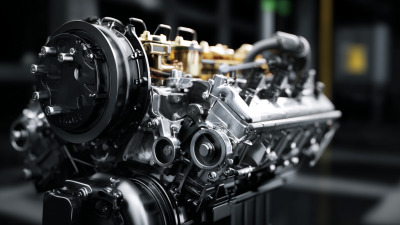

The advancement of diesel technology is revolutionizing modern machinery, with a strong focus on maximizing fuel efficiency. The introduction of the 824cc engine showcases innovative engineering that emphasizes optimal airflow, resulting in improved power and torque while maintaining exceptional fuel economy. This new engine design not only meets stringent performance standards but also aligns with increasing environmental expectations, proving that diesel can be both powerful and efficient.

Furthermore, the ongoing commitment to clean energy solutions is evident in new developments, including hydrogen engines and fuel cell systems. These innovations signify a shift towards embracing alternative energy sources while adhering to the indispensable role that diesel engines continue to play. By integrating cutting-edge technologies and expanding distribution networks, the diesel sector is poised to thrive in a competitive market, demonstrating that modern diesel engines can effectively combine performance with sustainability in today’s industrial landscape.

Unleashing Power and Efficiency with Diesel Engines in Modern Machinery - Maximizing Fuel Efficiency with Diesel Technology

| Engine Model | Power Output (hp) | Fuel Type | Fuel Efficiency (mpg) | Engine Weight (lbs) |

|---|---|---|---|---|

| Model A | 75 | Diesel | 25 | 500 |

| Model B | 120 | Diesel | 22 | 750 |

| Model C | 150 | Diesel | 20 | 800 |

| Model D | 200 | Diesel | 18 | 950 |

Integrating Kohler Diesel Engines into Various Industrial Applications

Kohler diesel engines have become a pivotal component in a variety of industrial applications, showcasing their versatility and robustness across multiple sectors. These engines are specifically designed to meet the demanding requirements of heavy-duty machinery in construction, agriculture, and manufacturing. By integrating Kohler diesel engines, industries can achieve enhanced power output while ensuring fuel efficiency, leading to significant operational cost savings.

In construction, for instance, Kohler engines power equipment like excavators and generators, providing reliable performance under extreme conditions. Their compact design allows for easy installation in various machines, while advanced technology ensures reduced emissions and noise levels. Similarly, in agriculture, these engines facilitate the performance of tractors and harvesters, boosting productivity through dependable power. By embracing Kohler diesel engines, industries not only optimize their machinery's performance but also contribute to sustainable practices through efficient energy use.

Maintenance Tips for Optimizing Kohler Diesel Engine Longevity

To maximize the longevity of Kohler diesel engines in modern machinery, implementing strategic maintenance practices is essential. Regular inspection and servicing can dramatically enhance the reliability and efficiency of these engines. Ensuring that oil and fuel filters are changed consistently, along with adhering to scheduled oil changes, can prevent the buildup of contaminants that could lead to engine wear and reduced performance. By maintaining clean components, operators can experience fewer breakdowns and disruptions, ultimately leading to increased productivity.

Incorporating advanced battery technologies can further optimize engine performance and maintenance. These technologies are designed to enhance reliability while lowering total operational costs. By reducing maintenance demands and extending service life, operators are better positioned to manage their fleets more efficiently. Adopting a holistic approach to engine care, including utilizing state-of-the-art power solutions, allows machinery to operate at an optimal level, ensuring that Kohler diesel engines remain powerful and efficient throughout their lifecycle.

Related Posts

-

Understanding the Role of Industrial Diesel in Sustainable Energy Transition

-

Unleashing Power: How Generator Sets Are Transforming Energy Solutions for Businesses

-

Maximize Your Power Supply: The Unmatched Reliability of Perkins Generators for Every Need

-

Explore the Advantages of Kohler Diesel Engines for Heavy Duty Applications

-

Ultimate Guide to Choosing the Perfect Marine Generators for Your Needs

-

The Ultimate Guide to Choosing the Right Small Diesel Generator for Your Needs