Explore the Advantages of Kohler Diesel Engines for Heavy Duty Applications

In the realm of heavy-duty applications, the choice of power systems is crucial for ensuring operational efficiency and reliability. The Kohler diesel engine stands out as a leading contender, renowned for its robust performance and durability. According to a report by the Diesel Technology Forum, diesel engines account for approximately 95% of all commercial construction equipment engines in the United States, underscoring their significance in heavy industries.

Kohler’s commitment to innovation and quality is supported by their diesel engines' exceptional torque-to-weight ratios and superior fuel efficiency, which can boost productivity while reducing operational costs. With an increasing focus on sustainability and compliance with stringent emissions regulations, the Kohler diesel engine also offers advanced technology solutions, making it an optimal choice for businesses striving for both environmental responsibility and performance excellence. This article delves into the myriad advantages of Kohler diesel engines for heavy-duty applications, providing insightful tips for industries looking to optimize their machinery.

Benefits of Kohler Diesel Engines in Heavy Duty Applications

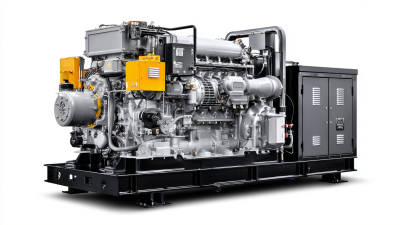

Kohler diesel engines are designed to meet the demanding requirements of heavy-duty applications, offering a range of significant advantages. One of the primary benefits is their exceptional power output and torque, which is crucial for operating machinery in industrial and construction settings. These engines are engineered to deliver consistent performance even under heavy loads, ensuring reliability and efficiency during extended use. The robust design and quality manufacturing of Kohler diesel engines contribute to their longevity and reduced maintenance needs, making them an economical choice for businesses.

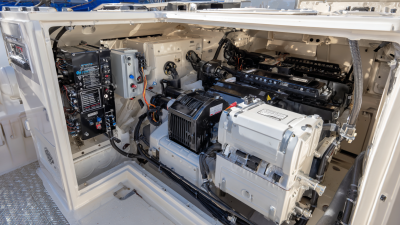

Another key advantage of Kohler diesel engines is their fuel efficiency. With advanced technologies that optimize combustion, these engines are capable of delivering high performance while consuming less fuel compared to many alternatives. This not only translates to cost savings for operators but also contributes to reduced environmental impact, aligning with the growing emphasis on sustainability in heavy-duty operations. Furthermore, Kohler offers a range of engines that come equipped with innovative features, such as easy service access and integrated diagnostics, ensuring that users can maintain optimal performance with minimal downtime.

Enhanced Fuel Efficiency: A Key Advantage of Kohler Diesel Engines

Kohler diesel engines are increasingly recognized for their enhanced fuel efficiency, making them a top choice for heavy-duty applications. In an era where operational costs are a primary concern, these engines stand out by delivering significant savings on fuel consumption. With the market for diesel generators in India projected to grow substantially, reaching an estimated $1.47 billion by 2024 and $2.59 billion by 2032, the demand for high-efficiency solutions like Kohler becomes more pronounced.

The construction generator sets market is also on an upward trajectory, forecasted to attain USD 16.4 billion by 2035, with a remarkable CAGR of 8.9% between 2025 and onward. This growth highlights a shift towards more sustainable and cost-effective power solutions. Kohler diesel engines, with their advanced engineering and optimized performance, not only meet the rigorous demands of construction and industrial applications but also contribute to reducing overall fuel expenses, thereby enhancing operational efficiency in today's competitive landscape.

Durability and Reliability: Why Kohler Stands Out in Tough Conditions

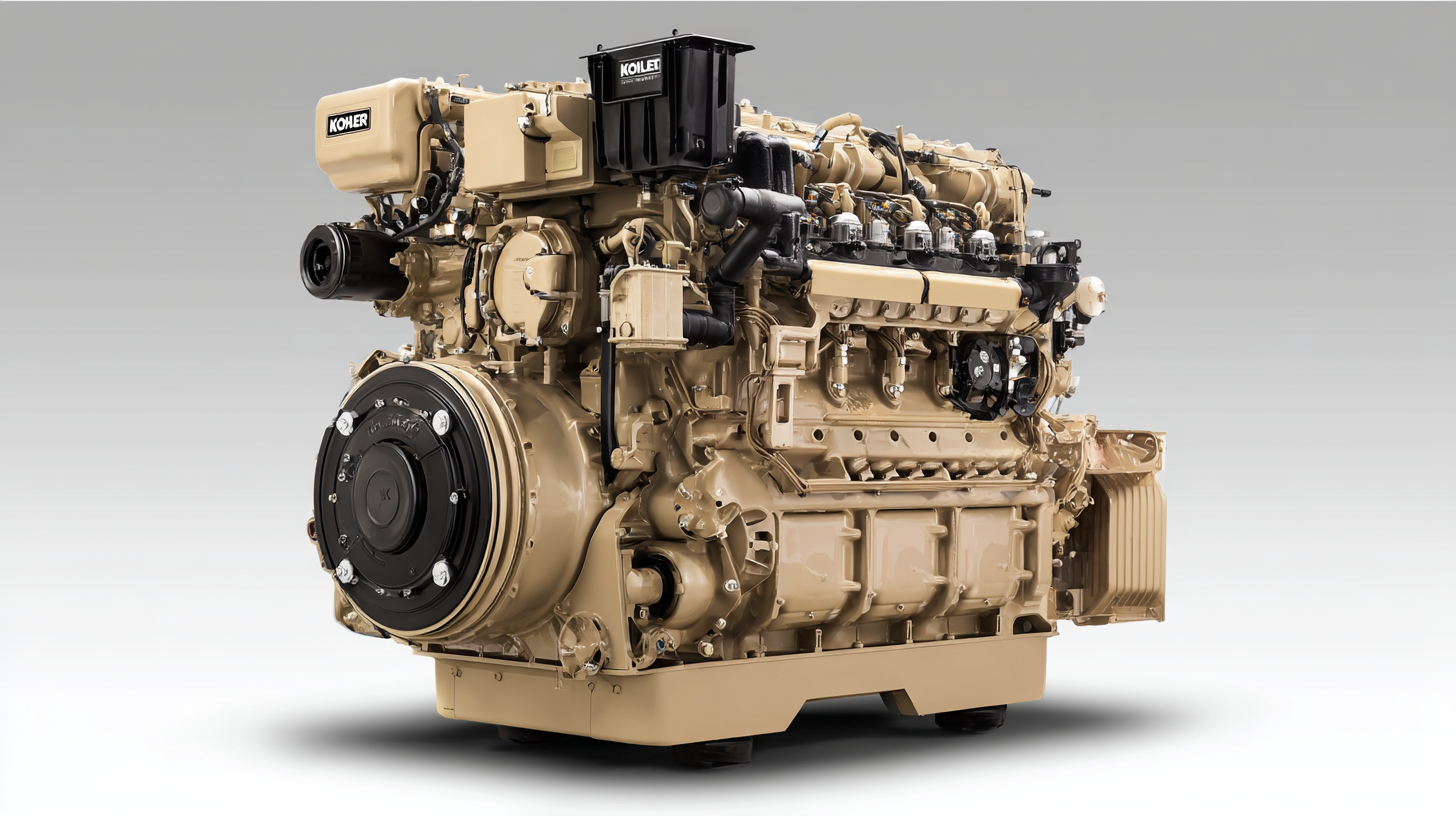

When it comes to heavy-duty applications, Kohler diesel engines are renowned for their durability and reliability. Designed to withstand the rigors of tough working environments, these engines are built with robust materials and advanced engineering that ensure long-lasting performance. Kohler's commitment to quality means that their engines can operate under extreme conditions, providing peace of mind to operators who rely on machinery in demanding industries.

Tips: When selecting a diesel engine for heavy-duty applications, consider the engine's maintenance requirements. Kohler engines typically offer easy accessibility to parts, reducing downtime during servicing. Additionally, investing in a preventative maintenance schedule can help maximize the lifespan of your engine.

Kohler also stands out due to its innovative technology, which enhances efficiency and power output. The engines are equipped with features that minimize emissions and fuel consumption, making them environmentally friendly choices without sacrificing performance. The combination of power and eco-consciousness is crucial for companies looking to maintain their machinery while adhering to stricter environmental regulations.

Tips: Be sure to explore options that offer remote monitoring capabilities, as Kohler engines can be paired with telemetry systems. This allows for real-time performance tracking, ensuring any potential issues are addressed promptly before they escalate into costly repairs.

Lower Emissions: Kohler Diesel Engines and Environmental Compliance

Kohler diesel engines are increasingly recognized for their advantages in heavy-duty applications, particularly in light of growing environmental regulations. With the India diesel genset market expected to expand from $1.47 billion in 2024 to $2.59 billion by 2032, demonstrating a CAGR of 7.39%, the demand for low-emission power solutions is critical. The emphasis on lower emissions aligns well with Kohler's commitment to environmental compliance, offering engines that meet stringent emissions standards without compromising performance.

Further, recent experimental studies on emissions from diesel engines using methanol-diesel blends reveal promising reductions in harmful emissions like carbon monoxide (CO) and carbon dioxide (CO2). This innovation not only enhances the environmental credentials of diesel engines but also highlights the potential for Kohler engines to adapt to cleaner fuel technologies. As the Asia Pacific diesel gensets market continues to grow, with forecasts suggesting significant advancements in technology and compliance standards, Kohler’s focus on lower emissions positions it favorably within the industry.

Explore the Advantages of Diesel Engines for Heavy Duty Applications

This chart illustrates the decreasing trend in CO2 emissions from heavy-duty diesel engines over the years. As manufacturers strive for environmental compliance, advancements in engine technology contribute to lower emissions. The data reflects a continuous improvement in emissions performance, highlighting the eco-friendly approach of modern diesel engines.

Versatile Applications: Kohler Diesel Engines in Various Industries

Kohler diesel engines are gaining traction across various industries due to their versatile applications and robust performance. These engines are commonly employed in heavy-duty machinery, construction equipment, and agricultural vehicles, where reliability and power are paramount. Their ability to handle demanding tasks makes them suitable for sectors that require consistent and durable equipment, such as construction, forestry, and mining. The efficiency of Kohler diesel engines in powering generators and machinery ensures minimal downtime, contributing significantly to productivity and operational efficiency.

Tips: When selecting a diesel engine for heavy-duty applications, consider the specific power rating requirements to ensure optimal performance. Engines in the 75-375 kVA range are often ideal for medium-scale operations, while those above 750 kVA cater to large industrial needs. Additionally, understanding the noise and emission regulations in your industry can aid in choosing an engine that not only meets power requirements but is also compliant with environmental standards.

Kohler diesel engines are also well-regarded for their fuel efficiency and lower emissions compared to conventional engines. As industries shift toward more sustainable practices, these engines support decarbonization efforts without compromising on power or reliability. This dual focus on performance and environmental impact positions Kohler engines as a formidable choice for businesses looking to enhance productivity while adhering to green standards.